Essential Materials Used in Air Filtration Technologies

This article explores the key materials used in air filtration systems, including activated carbon, stainless steel, paper, and cotton, highlighting their applications in ensuring clean air in various environments. It emphasizes the importance of selecting appropriate filtration media based on specific needs and pollutant types for optimal air quality and system efficiency.

Essential Materials Used in Air Filtration Technologies

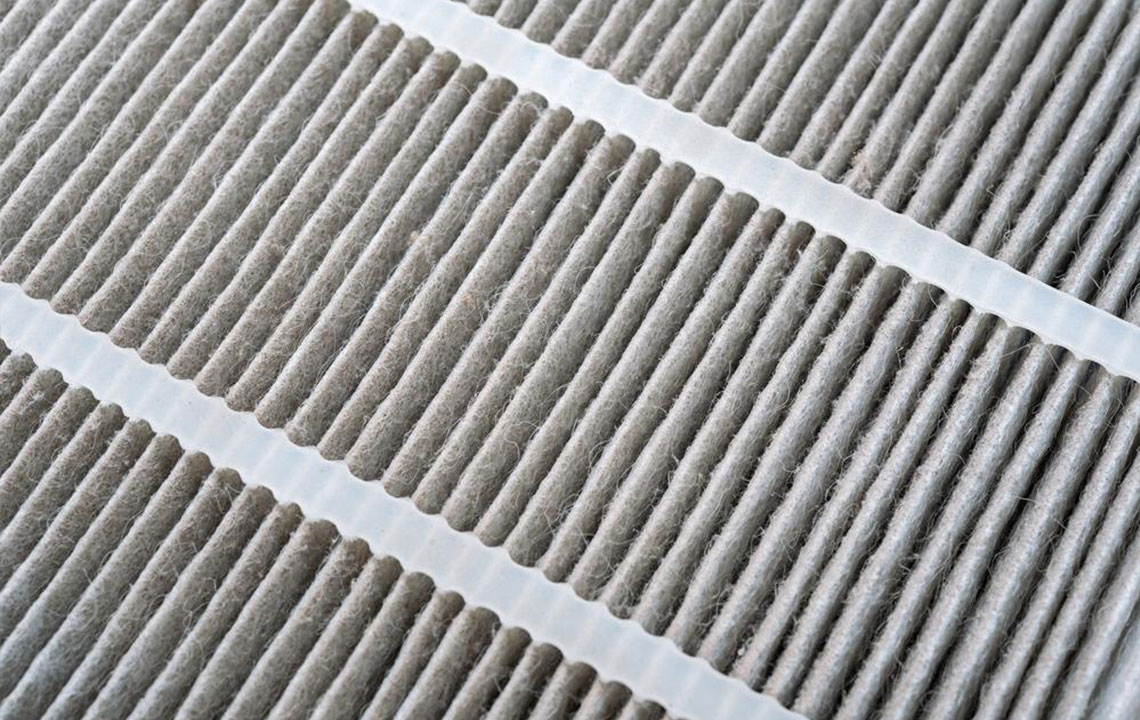

Air purification systems rely on specific materials to effectively remove pollutants like dust, bacteria, and harmful gases. These materials are crucial in ensuring clean air in environments such as aircraft engines and building ventilation setups. Technological developments have enhanced air filtration techniques through improvements in material science and aerodynamic design.

The selection of filtration media depends on the environment and pollutants targeted.

Since pollutant types vary by location, choosing suitable filter materials is vital. Commonly used substances include:

Activated carbon: Effective at neutralizing odors and gaseous toxins like ozone.

Polyurethane foam: Thick foam captures large particles; once popular in rally vehicles but now less common.

Electrostatic filters: Use high voltage to attract and eliminate airborne impurities.

Stainless steel mesh: Customizable pore sizes for different filtration levels.

Paper: Widely used in automotive filters due to affordability and ease of production.

Cotton: Emerging in use for air compressors, though less common.

Additional materials such as polyester, oil, and water baths are applied in specialized cases. Often multiple materials are combined for improved performance, balancing cost and effectiveness.

Choosing the correct filtration material ensures optimal air quality and device efficiency.

Note:

Our platform offers diverse informational content across various topics, supported by research and data. However, articles are for reference only and may not be comprehensive or fully accurate. We do not guarantee the accuracy of external schemes or offers that may benefit our readers.