Ultimate Guide to PVC Extrusion Equipment and Pricing in Mexico

This comprehensive guide explores the various PVC extrusion machines available in Mexico, detailing their features, benefits, and pricing ranges. It helps manufacturers choose suitable equipment to optimize production, enhance quality, and stay competitive in the growing plastics industry. Covering everything from basic single screw extruders to advanced high-speed models, it provides valuable insights for informed decision-making in the Mexican market.

Ultimate Guide to PVC Extrusion Equipment and Pricing in Mexico

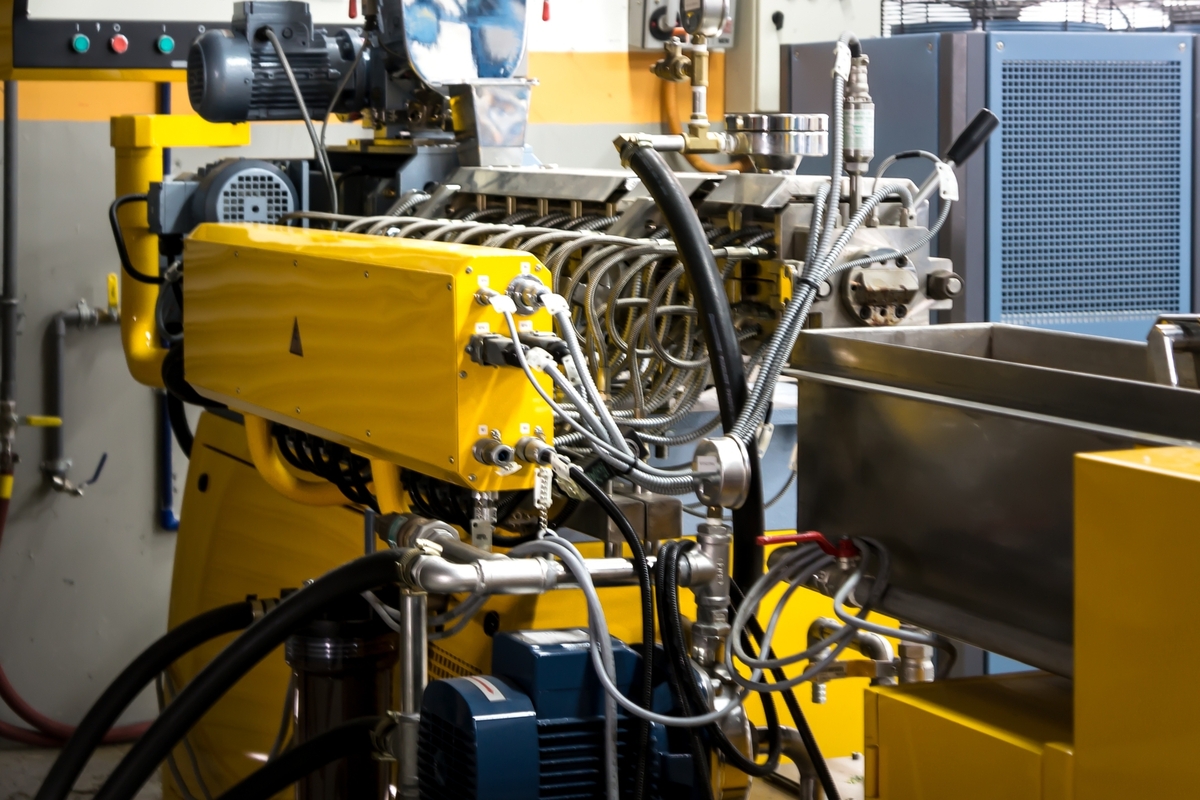

The plastics industry in Mexico depends heavily on PVC extrusion machinery to produce pipes, profiles, and sheets. The market offers a variety of machines tailored to different production needs and budgets. This article provides detailed information on the main types of PVC extruders available in Mexico, along with their price ranges, assisting buyers in making informed choices for their manufacturing operations.

1. Single Screw Extruders

Description:

This type features a single helical screw inside a barrel, designed for straightforward and efficient PVC processing. It’s suitable for producing basic products like pipes and sheets.

Benefits:

Cost-effective for fundamental PVC manufacturing.

Simpler to operate and maintain.

Perfect for basic products like pipes and simple profiles.

Price Range:

In Mexico, single screw extruders are generally priced between $20,000 and $80,000, depending on features and capacity.

2. Twin Screw Extruders

Description:

Equipped with two intermeshing screws, these units provide superior mixing, especially for PVC compounds with additives, resulting in higher quality outputs.

Benefits:

Enhanced material blending and homogenization.

Greater production efficiency.

Suitable for complex profiles and high-grade pipes.

Price Range:

Prices in Mexico for twin screw models typically range from $50,000 to $150,000, based on design, brand, and capacity.

3. Conical Twin Screw Extruders

Description:

Designed with conical screws, these machines improve feeding and melting, making them ideal for complex PVC formulations and larger pipe sizes.

Benefits:

Efficient feeding and melting of materials.

Suitable for larger and intricate geometries.

Energy-efficient operation.

Price Range:

In Mexico, costs range from $60,000 to $180,000, depending on specifications and manufacturer.

4. Parallel Twin Screw Extruders

Description:

Featuring synchronized parallel screws, these extruders provide consistent output and excellent dispersion, ideal for premium PVC profiles.

Benefits:

Uniform material processing.

Capable of producing high-quality profiles and sheets.

High throughput and efficiency.

Price Range:

In Mexico, prices vary from $70,000 to $200,000, influenced by capacity and features.

5. High-Speed PVC Extruders

Description:

Engineered for rapid production, these machines feature advanced controls to maximize efficiency, suitable for large-scale manufacturing.

Benefits:

Increased production capacity.

Precise operations with modern control systems.

Ideal for high-volume PVC output.

Price Range:

In Mexico, high-speed models start at $100,000 and can reach $300,000 based on speed and features.

6. Compact PVC Extruders

Description:

Designed for limited spaces, these compact machines are perfect for small and medium firms seeking efficiency without large footprint requirements.

Benefits:

Space-saving design.

Cost-effective for mid-sized production.

Easy to install and operate.

Price Range:

Prices vary from $15,000 to $50,000, depending on specifications.

Selecting the right PVC extrusion equipment is crucial for optimizing production and ensuring high-quality products. Mexico’s diverse market offers options from basic single screw systems to advanced high-speed units, fitting various budgets and processing needs.

Consider key factors such as capacity, material handling, energy efficiency, and after-sales support. Partnering with trusted suppliers guarantees reliability and ongoing maintenance, keeping manufacturers competitive.

Knowledge of the different types and costs of PVC extrusion machinery in Mexico enables smart investment choices, fostering growth and manufacturing excellence in the plastics industry.

Note: Prices are approximate and may vary based on supplier and customizations. For detailed quotes, consult local manufacturers. This content is for informational purposes and not professional investment advice.